Activewear has exploded in popularity over the last few years. From gym sessions to casual wear, more people want clothing that’s comfortable, durable, and looks good. Manufacturers now use advanced techniques to create better activewear. The two main methods are seamless and cut-sew designs. Each has its unique strengths and challenges. In this article, we’ll compare these techniques to help you understand which is right for your brand or sport.

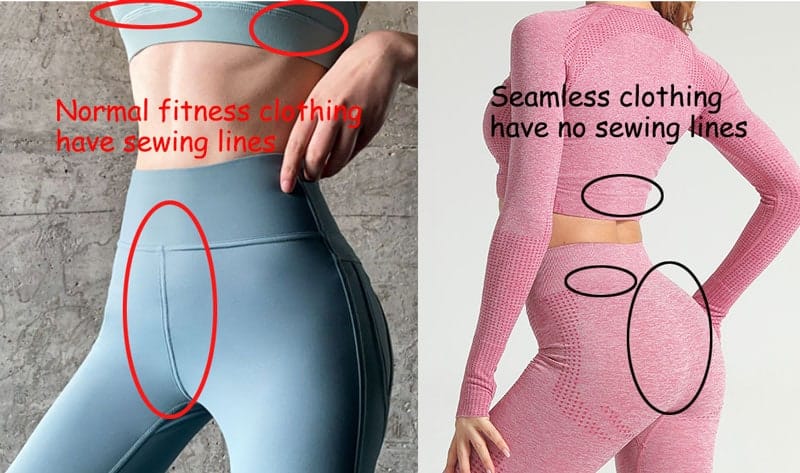

Seamless activewear is made using a special knitting process. This method creates a smooth, continuous piece of fabric without seams. It involves circular or warp knitting techniques, which produce stretchy, snug-fitting garments. Common materials include nylon, polyester, and elastane blends that stretch well and dry fast. The biggest benefits are comfort, as seamless pieces have fewer rub points, reducing chafing. They also tend to hold their shape better. You'll see seamless designs in sports bras, leggings, and compression gear, all thanks to their support and comfort.

Cut-sew activewear involves cutting pieces of fabric and sewing them together. This traditional manufacturing method gives designers more freedom in shape and style. Fabrics used include a wide range from cotton-blend to high-performance synthetics. One key benefit is the ability to add intricate details like panels, logo patches, or color-blocked sections. Cut-sew designs are popular in fashion-forward collections that aim for a unique look. They’re also great when a product needs a tailored fit or specific support zones.

Seamless garments are made using circular knitting machines that produce entire pieces in one go. This method is fast and produces consistent results. It’s well-suited for mass production because it reduces waste and speeds up manufacturing. However, the main downside is that design complexity is limited. Creating detailed patterns or multiple textures is challenging with seamless knitting. Plus, the machinery involved can be expensive upfront.

Cut-sew involves cutting fabric panels and sewing them together on a machine. This process allows for more creative freedom. Patterns can be complex, with multiple fabrics and colors combined into one piece. It’s easier to tailor the fit precisely to different body shapes. The main challenge is that it takes more time and labor. The seams, if not finished properly, can also cause discomfort from chafing or irritation.

Seamless manufacturing produces less waste because it’s a continuous process. Less fabric scraps are left over, making it a more eco-friendly option. In contrast, cut-sew creates fabric scraps that need disposal or recycling. Seamless techniques usually need less energy once the machinery is set up but require expensive equipment. Cut-sew can be cheaper initially but has higher labor costs.

Seamless activewear feels like second skin. It’s lighter and moves with your body, reducing irritation. But, if you want a more customized fit, cut-sew styles can be tailored exactly to specific needs. For example, added support zones or shaped panels improve performance.

Seamless designs tend to last longer. They resist tearing and tend to hold their shape over time. Cut-sew garments can be just as durable, especially if reinforced with extra stitching in key areas. However, seams can wear out faster if not carefully finished, and they may need special care to prevent fraying.

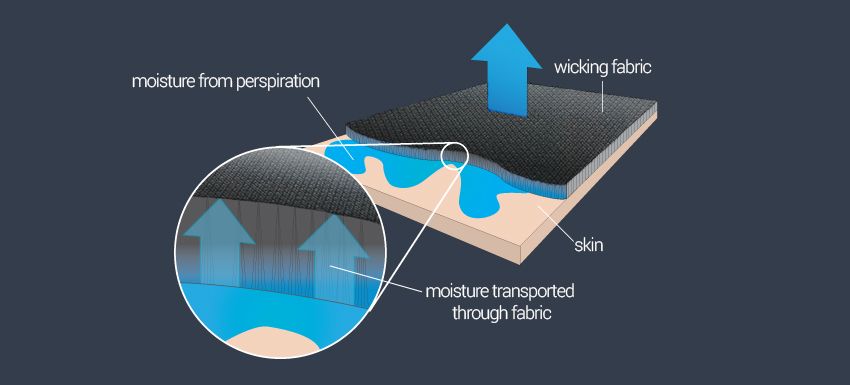

Both techniques can use high-tech fabrics that wick sweat and allow airflow. Seamless knitting often provides better stretch and support, which help during intense workouts. Cut-sew allows designers to incorporate different fabric types in one piece to maximize breathability in high-sweat zones.

Seamless designs offer a sleek, modern look. While they might seem simple, they can be quite stylish with color blocking, subtle patterns, or tonal variations. Limited by knitting techniques, complex details are hard to achieve but not impossible.

Cut-sew offers more creative freedom. Designers can add panels, mesh sections, or detailed logos. It’s the perfect approach for sportswear that needs a unique style. Fashion brands especially love this method for making pieces stand out on the shelves.

Brands like Athleta and Lululemon use seamless tech mainly in their compression and performance lines. Customers love the comfort and support these pieces offer. The feedback highlights how seamless activewear feels like a second skin — perfect for workouts and everyday wear.

Fashion-forward brands such as Nike and Adidas frequently use cut-sew techniques. Their collections feature bold patterns, textured fabrics, and intricate detailing. This approach helps them set trends and create eye-catching activewear collections.

Textile engineers often recommend seamless for high-performance gear where comfort is key. Designers favor cut-sew when style and detail matter most. Industry data shows consumers increasingly want activewear that’s both functional and fashionable—each technique plays a vital role.

Both seamless and cut-sew activewear have their place. Seamless excels in comfort, ease of production, and sustainability. Cut-sew offers unmatched flexibility, intricate design options, and precise fitting. Your decision should depend on your brand goals, target audience, and athletic needs. As technology advances, expect more hybrid options and innovative solutions. Choosing the right technique ensures your activewear stands out and performs well, no matter the activity.